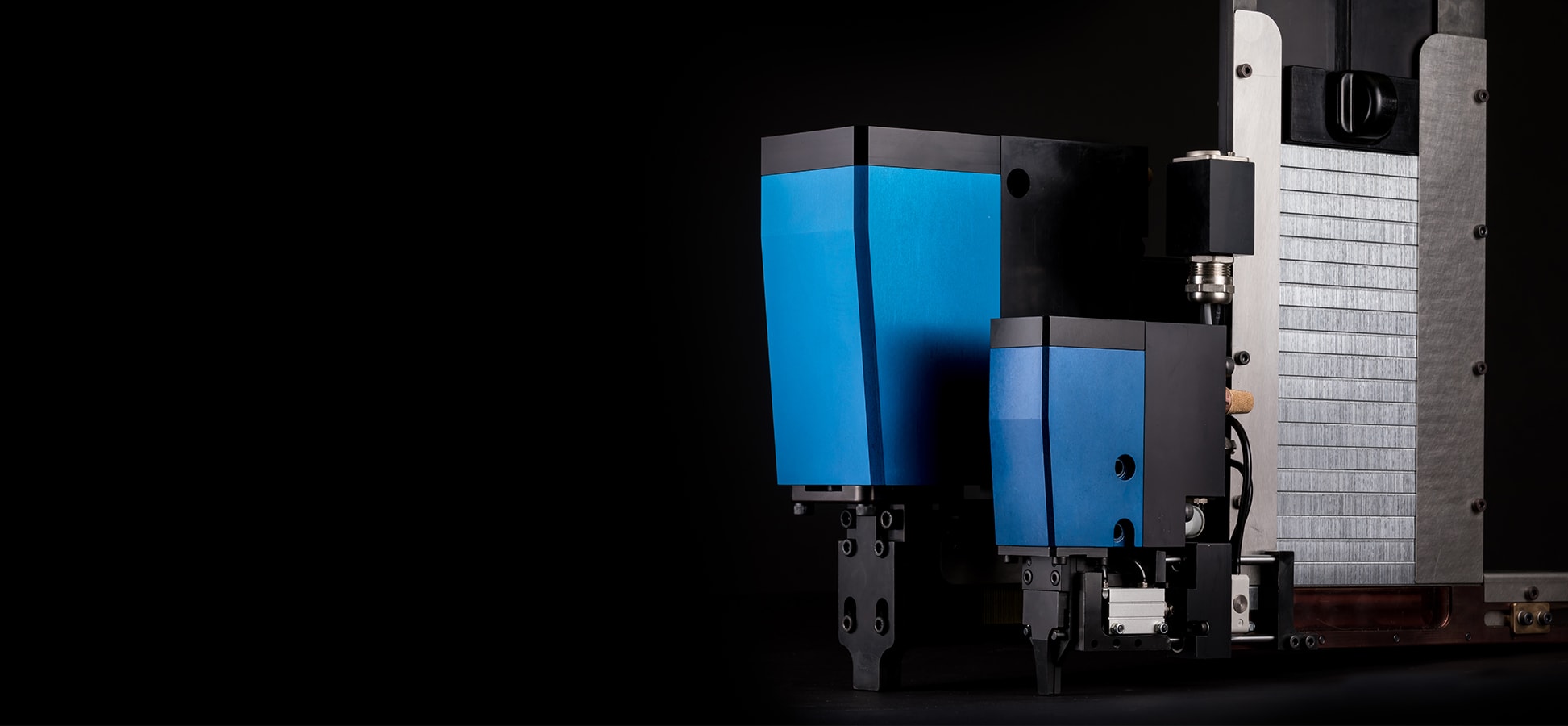

Automated Fastening System JK A-Fast A1 A3

Automated Fastening System Models For Your Needs

With our automated fastening system, you can take your manufacturing to the next level.

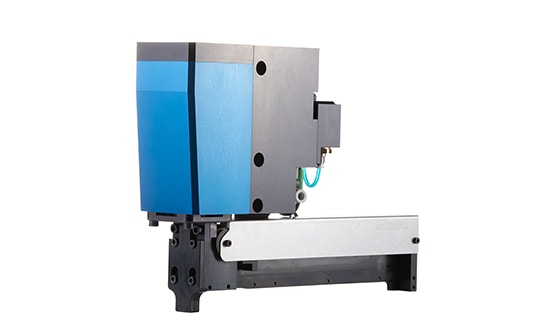

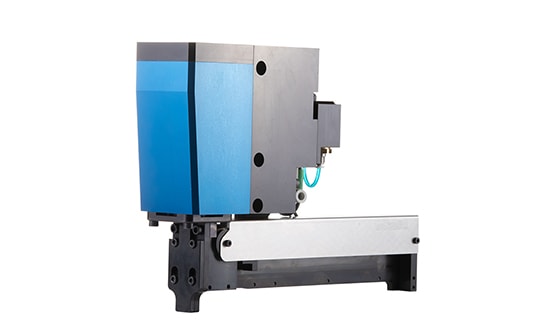

JK A-Fast A1L 670 | 680 | 690 | 780

Automated fastening system with long magazine

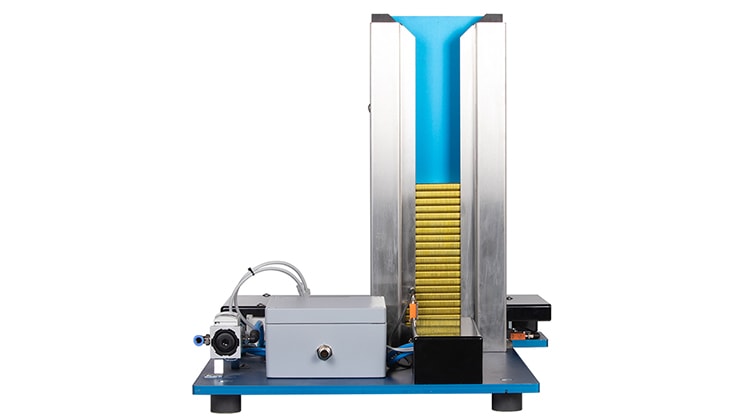

JK A-Fast A1H 670 | 680 | 690 | 780

Automated fastening system with high loading magazine

JK A-Fast A3L 653 | 783

Automated fastening system with long magazine

JK A-Fast A3R 653 | 783

Automated fastening system for robot mounting

Features Automated Fastening System

Electric connector

Our units use a single electric connector for all functions. The connector makes it easy to install and perform effortlessly for maintenance or service disassembly.

Electric or pneumatic

Our automated fastening systems are available in both electric and pneumatic actuation, so they can easily be integrated into your production.

Magazine sensor

The magazine sensor controls the staple loading status. The sensor warns you when the magazine reaches low levels. Furthermore, it allows you to refill the magazine without interrupting production flow.

Feeding controller

Poka-yoke: This function warns when your automated fastening system is not firing any fasteners. It gives you full control of your staple consumption.

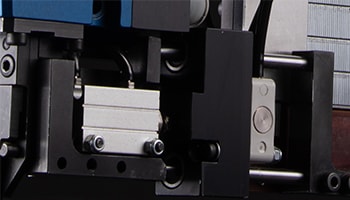

Continuous reloading cylinder

Our precision engineered continuous reloading cylinder makes it possible for autonomous staple firing at high speed. The reloading cylinder ensures that reloading fasteners are produced efficiently from the magazine. Only for A1H models.

Split free nozzle (A3)

Avoiding splits and cracks when fastening wood on wood is a must in manufacturing. Josef kihlberg’s patented split free nozzle solution prevents splits in material when fastening.

Accessories Automated Fastening System

Reloading station A3R

To get the most out of your workflow with A3R our reloading station extends your loading capacity of fasteners with an external magazine. The robot reloads the magazine automatically in the reloading station, which minimizes downtime in production. It is easy to install and comes with a small flexible tool for robot mounting.

Automated fastening system for robot

See our A3R783 model in action

Full System Solution

Automated fastening systems

Josef Kihlberg in-house Production

With over 175 years of proven experience, we understand the importance of working closely with our customers. To understand your needs and make high quality and professional products that make the difference for your business. We take great pride in the fact that you can rely on our tools & staples. That is why we research and produce our products in-house in our factory in Hjo Sweden. Our Quality control guarantees the highest quality processes throughout the manufacturing process.

Tools and staples designed together for perfect performance

No system is stronger than the weakest link. That’s a fact for you, for your competitors and us. We know that every little detail counts to get a competitive advantage and for a production line to function well. Therefore all parts of Josef Kihlbergs automated fastening systems are designed for optimal performance and are thoroughly tested. You can be sure that every single part achieves and works in perfect symbiosis with each other.

Flawless functionality for highest UPtime

The only thing better than having a reliable production line is having one that also produces efficiently. That’s why we created these systems. So your business can focus on what matters, revenue growth and optimal productivity. With our integrated system of carefully selected components, which stand the test of time, you can take your business to the next level. By minimizing downtime and maximizing output.

High Reliability

Automated fastening systems

Durable design & components

We don’t cut corners when it comes to our high-quality components. We carefully select our parts and do comprehensive testing. If a component doesn´t stand up to the high standards of Josef Kihlberg, we won't use it.

Built for 24/7 operations

Our Automated Fastening Systems are built to maintain productivity around the clock. It´s quality engineering and construction to meet the demands of a high labor intensive workload.

Long service intervals

All of our products come with long service intervals due to its high-quality parts and precision engineering. That is what our automation systems are all about.

High Availability

Tools and spare parts on stock

We have ensured that all your tools and spare parts will delivered as fast as possible, so you can get the work done and operate with peace of mind.

Guaranteed shortest lead times

You have a promise to your customers. We understand that. So we have a promise to you. We work towards having the shortest lead times on all our tools and spare parts.

High Speed & Low Sound Emission

The speed you need

Our secure fastening technology gives you the speed you need when fastening your material. 750 shots per minute for A1 and 500 for the A3 models.

Low sound emission

We are true believers of good work environments. Therefore we create our automation fastening systems to produce to very low sound emissions.

SMOA & JK-AFT Technology

SMOA

Josef Kihlbergs SMOA technology is a safety function for maintenance that prohibits the unit from firing when airflow is connected.

JK-AFT

JK-AFT(Air Flow Technology) for the A3 model makes the unit powerful even at low air pressure. This technology will save air consumption for your application, which will reduce costs for your business.

Benefits Of Automated Fastening System

Reduce cost of production

A quick ROI from initial set up. Better throughput.

Higher quality levels

Manufactured to the same specifications each time. Better end product then manual work.

Increased productivity

Higher efficiency and overall labor effectiveness then manual work. Produce more in less time.

Shorter cycle times

Constant production without stopping breaks for workers. Produce more in shorter time at same speed then manual work.

Reduced waste

Better use of raw material. Makes production process more accurate and thereby decreasing manufacturing costs.

Increased safety

Increased workplace safety. Less hazardous and dangerous manual tasks. Risk minimizing.

Increased savings

Less insurance cost for workers. Quality output increases customer satisfaction and customer retention.

Better performance

Can perform more labour intensive tasks then manual work.

Automated Fastening System Unit Material

Automated fastening system material

All of our Automation fastening systems are made in aluminum, stainlees steel and steel. It´s extremely durable and requires almost no maintenance.

We're testing your material

Our automatic stapling systems can handle most materials. When in doubt, we test your materials so you can be sure that it works in your production.

A3R With Split Free Nozzle

Automated fastening system for robot