Clog stapler

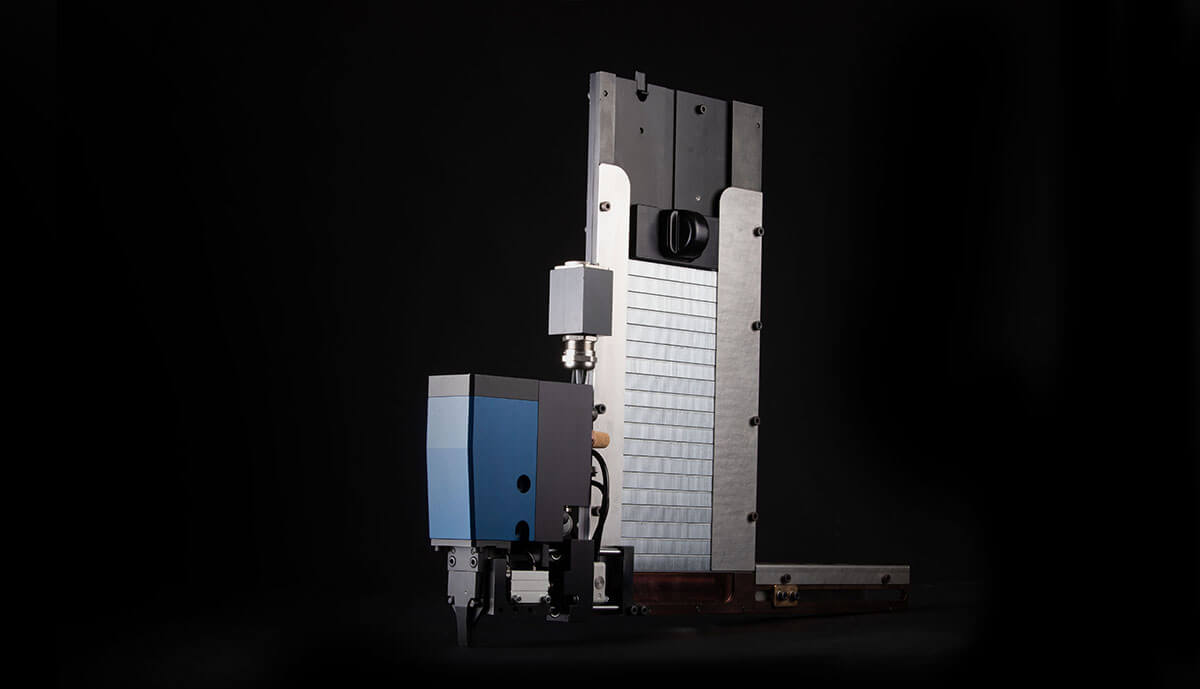

Automated clog stapler for manufacturing A-Fast A1H-780

Automated Clog stapler

We built our automatic clog stapler unit with the understanding that every pair of clogs comes with a history of craftsmanship where every little detail counts. At Josef Kihlberg´s, we have been producing stapling units and staples for the clog industry for decades. Therefore we know the great importance of working closely with clog manufacturers to ensure their knowledge, skill, and dedication can be used in symbiosis and efficiently with our automated clog stapler unit. The unit is suitable in any production environment.

Design

Made with the utmost respect for the craft of clog making

Slim design

The slim design of A1H-780 comes with many benefits. It is easy to install in existing workstations. It’s ergonomic and easy to work with for the operator. Furthermore, the operator can get closer and will get a better overview of the stapling process, leading to increased uniform lines, which results in a better and more professional end product.

High stacking magazine

Our clog stapler´s magazine is a high stacking magazine with excellent loading capacity. Depending on the staple leg length your clog uses, you can load it with up to 1010 (19mm) (22mm) or 1430 (16mm) staples. Meaning you can work efficiently longer, minimizing the stops for reloading the magazine.

Features

An automated clog stapler packed with features

The speed you need

The A1H-780 is fast while maintaining excellent control and stability throughout the stapling process. Even at high speeds up to 750 staples per minute, it´s easy to work with and produces high-quality results.

Powerful

With great power comes great responsibility. The A1H-780 knows this very well. It handles the joining process gently meaning it minimizes splints and impact damages when fastening to sturdy wood materials with living materials like leather.

Minimal recoil

e A1H-780 produces minimal recoil when firing. That’s a testament from our excellent engineers at Kihlbergs, who strive to make the best tools both for the application and the people who use it. For you, this means fewer work-related injuries and a safer work environment.

Continuous reloading cylinder

Our precision-engineered continuous reloading cylinder makes it possible for autonomous staple firing at full speed. The reloading cylinder ensures that reloading fasteners are produced efficiently from the magazine.

Low sound emissions

The A1H-780L has low sound emissions that meet the requirements of a modern workplace. The unit is precision-engineered to balance its raw power with minimal impact noise.

Adjustable nozzle

The clog stapler comes with an adjustable nozzle which makes it easy to adjust the staple impact for your materials and air pressure.

Easy to work with

Feel the difference

Ease of use

The automation clog stapler unit is easy and enjoyable to operate. A1H-780 has an excellent balance, the slim nozzle which makes it easy to fire in uniformed lines while keeping full control. Futhermore it makes it easy to go around corners while stretching the leather and fastening it to the wooden base of the clog. The clog stapling unit and the JK780 staple work together in perfect symbiosis, meaning fewer jam ups and an optimized workflow.

A reliable clog stapler

When the orders come in, and products fly off the shelf. It is vital that production flows and does not come to a halt. With over 178 years of experience with tools and staples, we know the importance of reliability. So you can produce high-quality products and minimize downtime. Our automatic clog stapler unit can be used over and over again and will maintain its performance levels. Josef Kihlbergs A1H-780 will be your loyal companion for many years when performing your craft.

Staples for clog manufacturing

Made for the craft

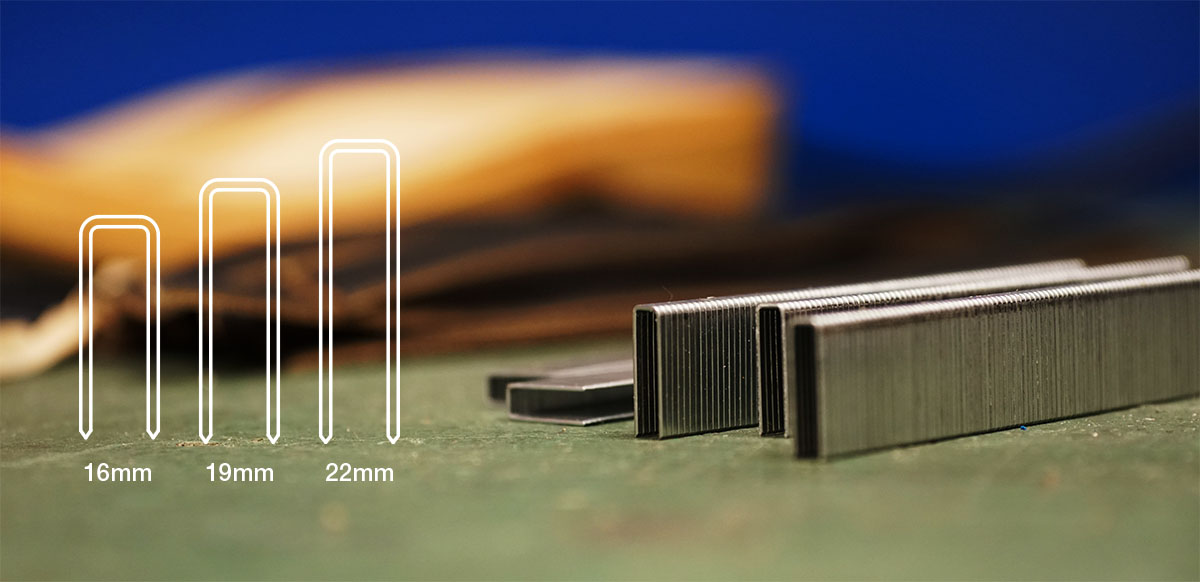

JK780 – A staple specialized for clog manufacturing

The JK780 is a staple specialized for clog manufacturing. The staple´s design handles the material with respect, whiles forming an excellent joining between the leather and wood as well as the rubber sole to wood and leave no glue residue. The staple handles sturdy wood material such as alder, birch, beech, poplar, and other wood materials with ease. The JK780 provides a reliable and lasting hold for manufacturers with a premium look for end users.

Technical data

Automated Clog Stapler |

A1H-780 |

|---|---|

| Weight | 4.6 – 6.0 kg (10.1 – 13.2 lbs) |

| Dimensions | 484 x 74 – 82 x 404 mm (19.1” x 2.9 – 3.2” x 15.9”) |

| Magazine capacity | 1010 – 1430 pcs |

| Speed | 750 shots/per minute |

| Working pressure | 5 – 6 bar (70-90 psi) |

| Max. pressure | 7 bar (100 psi) |

| Air consumption per driving operation at 6 bar (90 psi) operating pressure |

0.35 liter |

| Air supply | Filtered, slightly oiled-air tube, 8 mm (outside diameter) |

| Power supply | Pneumatic |

| Staple leg length | 16mm, 19mm, 22mm |

Features |

| Feeding controller | X |

| Continuous reloading cylinder | X |

| Automatic firing option | X |