Cordless Carton Closer – Battery Top Stapler c.561B a.560B

Cordless carton closer c.561B a.560B

See it in action.

Ergonomic cordless carton stapler

Top stapler designed for the user

The lightest battery top stapler

The tool is extremely light and easy to use. Its weight is only 2.7 kg (6lbs), meaning that you can use it for prolonged times and take it with you wherever you go without suffering from arm fatigue.

Ergonomic handle

The unit has an ergonomic handle with a soft rubber grip. The grip gives the user high comfort during extended periods of use, whiles also providing a more secure grip when operating with the tool.

Mobility

Our cordless packaging closer gives you excellent maneuverability, allowing for optimal posture when operating it. The top stapler is incredibly kind to the operator’s health. The design of the tool makes it easy and enjoyable to use in different positions while giving excellent carton closing results time after time.

Smoothest recoil

Our box closing stapler´s state of the art technology ensures excellent balance. It dampens the vibrations from recoil during the prolonged and repetitive operations of daily use. Gone are the days of arm injuries from recoils.

Swiss engineering

Efficient

Our cordless carton closing top stapler gives you the speed you need and a competitive advantage

Fastest battery stapling tool

We are proud that our cordless carton battery stapling tool is the fastest in the world. It can fire up to 5 shots per second. The speed you need at all times for a faster stapling process and higher overall productivity.

8000 staples per battery charge

The tool delivers the most carton closing from every charged battery. Our cordless box closing top stapler is precision engineered to be able to fire up to 8000 shots per battery. Giving you the capacity you need to be more efficient and longer tool uptime.

Brushless wear free motor technology

Our brushless motor technology gives you significantly higher efficiency and performance compared to a brushed motor. It increases reliability and needs fewer maintenance efforts due to its lower susceptibility to mechanical tear, which means that the cordless carton closer has a longer lifespan than its brushed motor counterparts.

Lowest sound emission

When we designed this tool, we had performance, ergonomics, and work environments in mind. To be able to produce the lowest sound emission, the top stapler uses a brushless motor which reduces the operational and mechanical noise from the unit. Our battery powered stapler produces half the sound emissions compared to pneumatic carton closers.

Easy

Our cordless carton closer is easy to learn and use.

Digital User Interface

For full control of your cordless top stapler

Indication battery status

The indicator shows the charging status of your cordless packaging stapler. Levels are maximum, high & empty.

Indication operation mode

The indicator easily visualizes which operating mode you are using. Where blue is the active mode and white are inactive mode.

Mode selection button

The cordless carton stapler has an easy one click switch operation mode and an optional hold down to activate/deactivate laser positioning mode.

Operating Modes

Intuitive and easy to use.

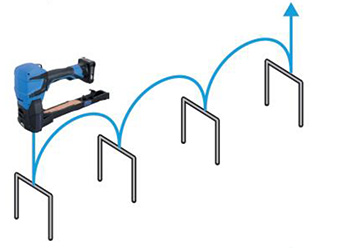

Manual Stapling

Single staple insertion by manual trigger actuation. Recommended for varying packaged goods (soft, hard).

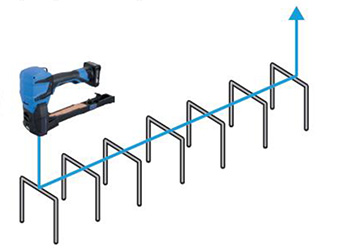

Semi-automatic stapling

Multiple staples can be inserted with continuously held trigger actuated via box detection sensors. Recommended for large quantites of identical packaged goods.

Automatic stapling

Multiple staples can be inserted over a predefined interval by continuously held trigger. Recommended for large quantites of identical packaged goods or long packages.

Laser guidance position system (Option)

Ensure high-quality brand packaging every time.

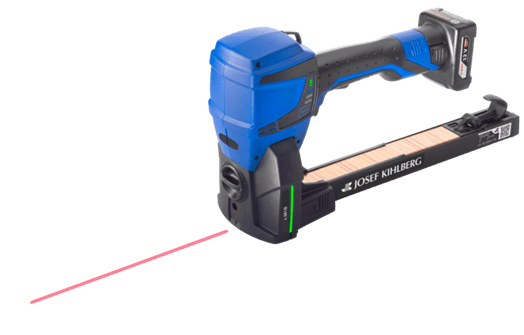

Front laser

For positioning guidance with one front laser.

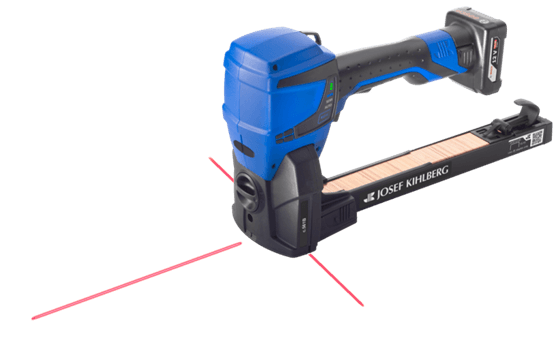

Cross laser

For positioning guidance with one front and two side lasers.

Benefits laser guidance position system for carton closing

Minimizing human errors

The laser guidance positioning system reduces potential human errors when closing cartons — giving you happier and more consistent users.

Maintaining high-quality standards

With both front laser and cross laser, you can achieve high-quality box closing and ensure brand quality on every single package.

Great for the training of new users & seasonal workers

The guidance laser positioning system makes it intuitive, fun, and easy to use. New users will quickly learn how to use the tool efficiently and the right way.

Makes alignment faster and more efficient

The guidance laser system gives you a competitive edge. You will get faster alignment and a more efficient workflow every time. The laser guidance positioning system makes it easy to achieve tremendous and professional results in difficult positions.

Less labor intensive

It is less labor intensive when using the laser positioning system. It removes the additional calculation of measurement and positioning for every single staple and package, making top stapling more intuitive, more accurate, and more enjoyable to use every time.

Safer work environment

The guidance laser system makes it easy and clear where your staples are shot and therefore, minimizing the risk of work-related injuries when stapling. The positioning laser makes the tool easy to use in dimmed or dark environments.

LED indication

For full control of your cordless top stapler

Blue LED

Slowly pulsating

“Ready for operation”

Green LED

“Permanently on

“Tool in stapling position”

Magazine quick snap system

Our battery powered carton top stapler comes with a safe magazine quick snap system. It is quick and easy to remove and have a safety feature which makes it impossible to fire by accident during maintenance.

Safety

We built our units with the utmost respect for workers safety. Our top stapler only works when all three safety features are active - ensuring the highest operating safety.

Safety latch

Our top stapler has a mechanical safety latch in the handle. The safety latch forces the operator to use the tool correctly and safely.

Box detection

The unit has optical sensors built into the bottom plate for electronic box detection. The box detection ensures that the operator cannot fire the top stapler without material under it.

Trigger finger detection

Carton closing has never been safer with our optical sensor built into the trigger. It electronically detects when a trigger finger is present, and it prohibits operators from manipulating the trigger, giving you the maximum safety.

Maintenance safety

The tool ensures maximum safety at maintenance. When the magazine is removed, the tool is in lockdown mode, making it impossible for the top stapler to fire by accident.

Economic

You can save a lot of expenses with our cordless top stapler.

Infrastructure costs

There are several benefits of choosing a battery carton closer over its pneumatic counterpart. The following expenses can be saved with a battery driver carton closer: space for compressor, noise absorber, lubrication, fittings, tubing, and fixed stations.

Maintenance costs

You can save a lot of maintenance cost with a battery-driven top stapler. Examples of maintenance cost savings include compressor, fittings, connections, safety checks, finding air leaking points, air consumption, and energy savings.

Energy costs

A lot of energy expenses is saved with a battery stapler. You only consume energy when you are using the tool. There are no costs for transforming electric power to pneumatic power, moreover the energy cost of keeping air cooled and maintaining air compressed in an air reservoir.

Cordless carton stapler - the future is now

Unlimited freedom with our cordless carton closing top stapler.

No power outlet

A significant advantage of our top stapler is that there is no need for a power outlet when operating the tool. It´s only needed when charging the battery.

Mobility

The more mobile you can be, the more you can adapt to changes and situations. Processes can be simplified, and the tasks are performed on the fly.

Less equipment

A battery powered box stapler makes the workspace less crowded. Furthermore, it decreases the cost of installing and maintaining the surrounding equipment to be able to operate.

Fewer injuries

With our cordless carton closing stapler, you will minimize work-related injuries. Less equipment means less clutter in the workplace. It reduces potential situations where injuries can occur. Tripping over cords is a thing of the past.

Less strain

A cordless top stapler put less strain on the operator, whereby a corded tool puts more downward force on the tool.

Freedom

The battery top stapler gives you maximum freedom, and you can move freely. You can take it with you wherever you are. Performing in remote areas is a breeze with our top stapler.

Battery for top stapler

Our top stapler uses a premium 4.0Ah high-performance Li-Ion battery from Bosch. Firing up to 6000 staples per charge

High energy density

The Li-Ion battery has a high energy density, which is one of its most significant advantages of the technology. It means that the battery can operate longer between charges.

Rapid charging

The Li-ion battery charges more rapidly than other battery types and ensures a longer runtime. Charge time is approximately 60 minutes for 80% and 80 minutes for 100%.

Electronic cell protection

The electronic cell protection (ECP) protects the battery and ensures a long lifetime. It gives the battery protection against overload, total discharge, and overheating.

No self-discharge

The battery technology has no self-discharge and no memory effect. This means that it will not affect the battery capacity during the charge and discharge.

Extremely robust

The battery is exceptionally durable and can handle rough work environments. The casing has a sturdy construction and is shock resistant.

Low maintenance

The lithium-Ion battery is a low maintenance technology. It requires no maintenance to ensure its high performance. It has no memory and does not need scheduled cycling to prolong battery life.

Staples for cordless top stapler

No system is stronger than the weakest link

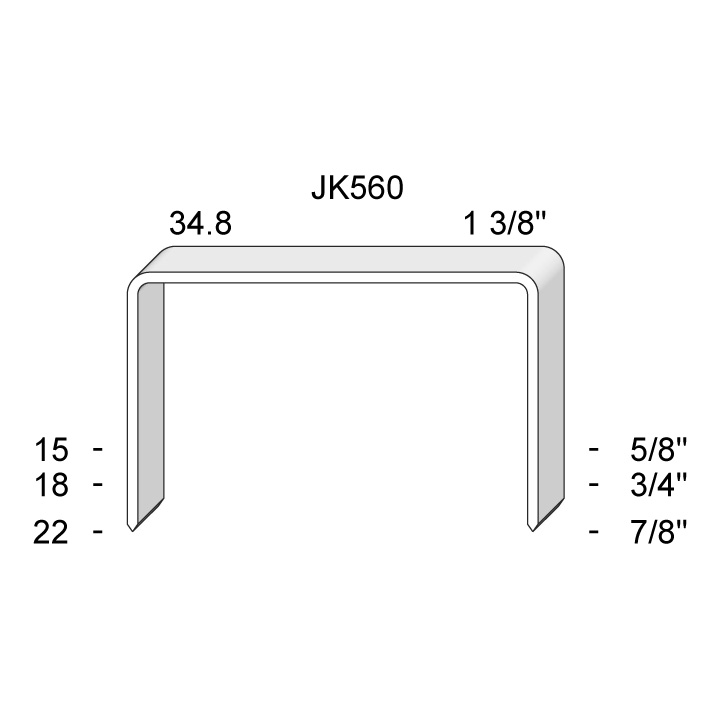

JK560

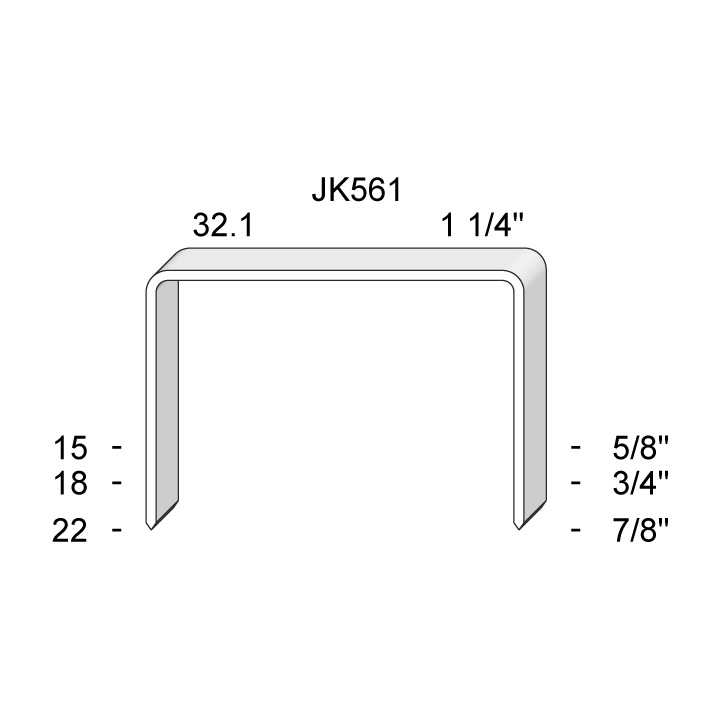

JK561

Certifications

Ensuring high quality all the way

CE Certification

Our battery powered top stapler conforms with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Click here EU´s website for CE declaration.

Videos

Get started with your cordless carton closer

Training

01

Getting started

Package content

Loading the staplers magazine

Charging the battery

02

Settings

Setting stapler type

Adjust penetration depth

User interface

03

Operation

Activating the stapler

Operator safety features

LED tool status indication

Operation modes

Option: Laser positioning

Maintenance & Cleaning

Driver blade

Clincher

Carton closing stapler FEFCO standards

Our Carton closing battery top stapler handles many FEFCO standardized corrugated boxes. If you are unsure if it works with your packaging, we will gladly help you and share our expertise.

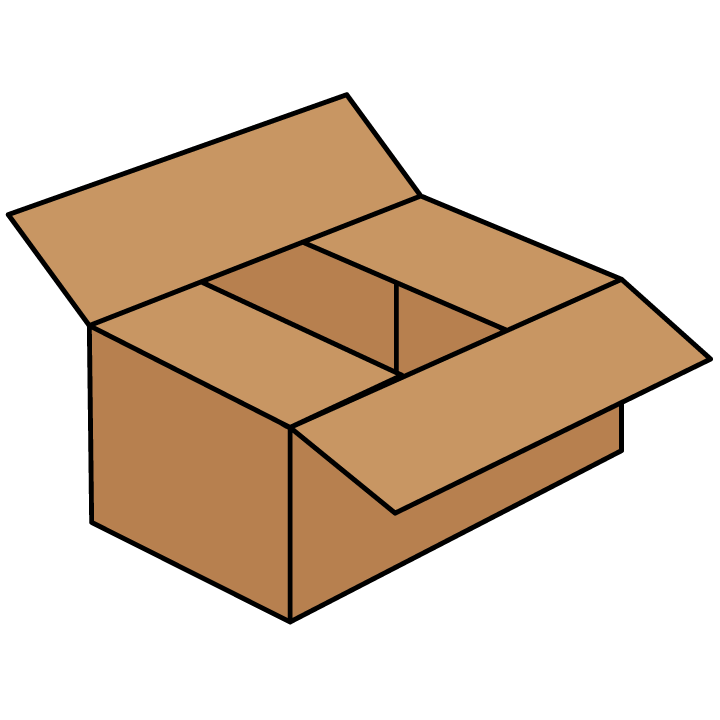

FEFCO 0200 Styles

Slotted boxes

0201, 0202, 0203, 0204, 0205, 0206, 0207, 0210, 0211, 0212, 0215, 0216

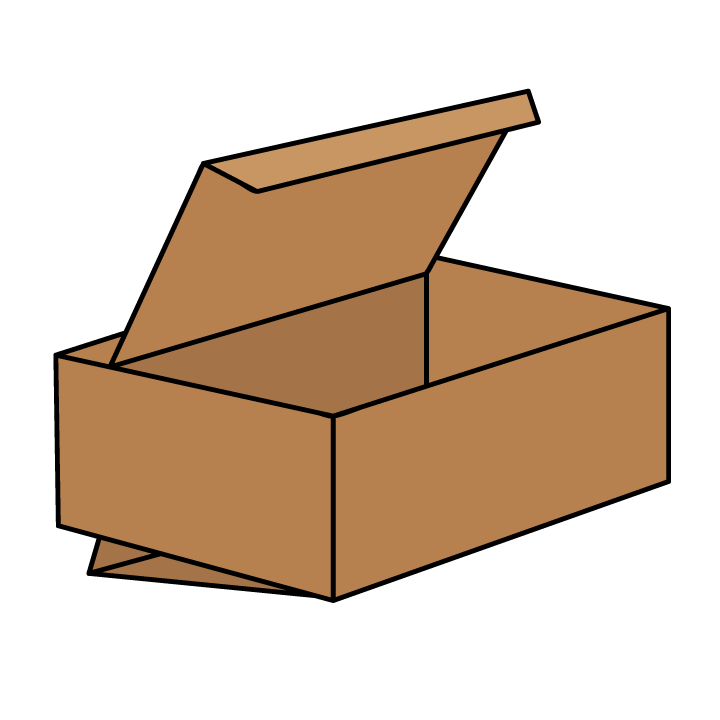

FEFCO 0300 Styles

Telescope boxes

0300, 0301, 0320

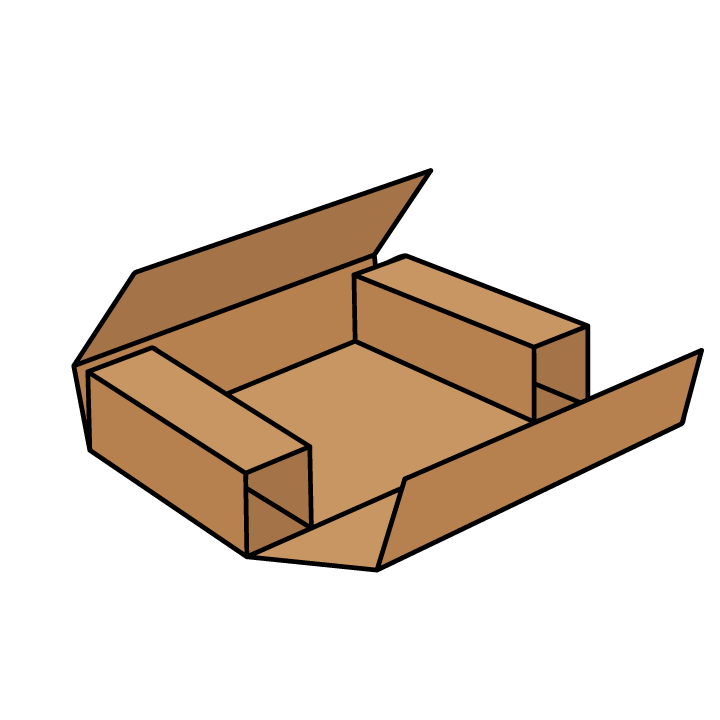

FEFCO 0400 Styles

Folder boxes and trays

0403, 0413, 0420, 0421, 0426, 0427, 0428, 0429, 0441, 0442, 0443, 0444, 0470

FEFCO 0500 Styles

Slide boxes

0510

FEFCO 0700 Styles

Pre-closed carton

0701, 0711, 0712