Staple guide - All you need to know about staples

This guide provides you with information about how you can choose the right type of staples for your application.

It covers the following topics: staple body parts, staple wire types, staple crown types, staple leg lengths, staple material, staple points, and staple clinch.

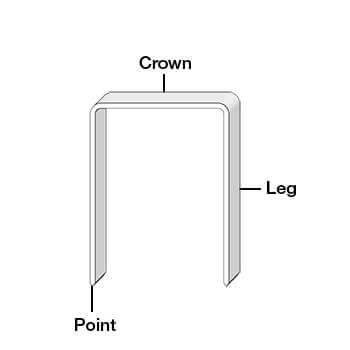

Staple body parts

How to choose the correct staple wire

When we talk about the staple wire, we mean the thickness of the staple (the staple wire diameter). For simplification, we divide the staple wires into the following three categories, fine wire, medium wire, and heavy wire — all with their specific uses for different applications.

Fine wire

Fine wire staples are the thinnest type of staples. It is for delicate applications where the staple needs to be discrete with low visibility and where the back of the staple should be unexposed. Fine wire staples are the most common type for upholstery and framing because it has a minimal effect when attaching fabric (textiles) to wood or plastic. And it is the go-to wire when you work with breathable membrane or vinyl.

Applications:

Furniture Upholstery, Vinyl, and trim, Picture frames, Automotive upholstery, Labeling

Our fine wire staples:

JK670 JK680 JK689 JK690 JK779

Medium wire

The next step up from fine wire is medium wire staples if you need a thicker staple for your application. A medium wire staple is an excellent staple for upholstery, but compared to a fine wire staple, it produces more holding power. This type of staple has a superb wood on wood joining capability and is therefore often used in manufacturing where the fine wire staple is not enough. The medium wire is also widely used when joining with plastic.

Applications:

Furniture, Pallet, Crate, Sheathing, Subflooring,

Packaging

Our medium wire staples:

JK53 JK777 JK781 JK782

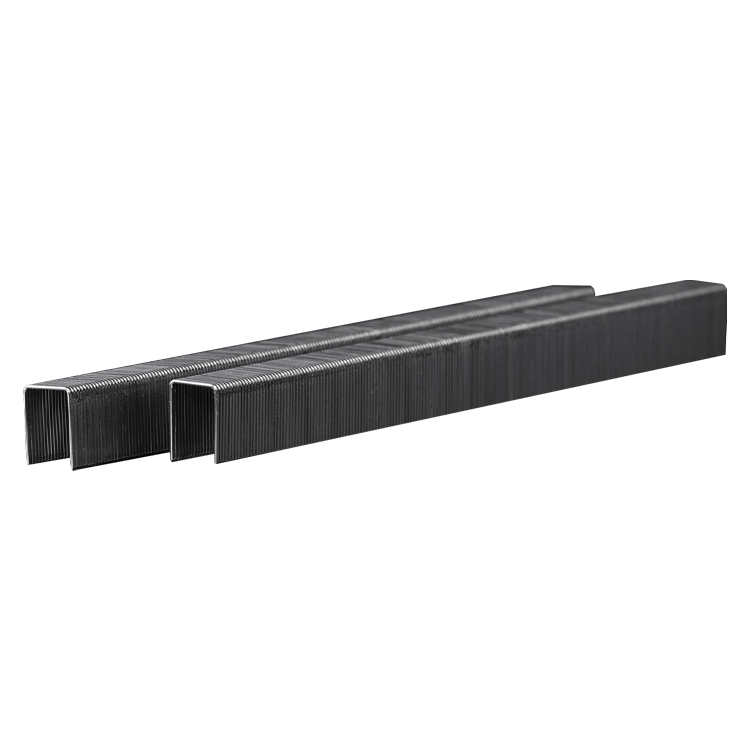

Heavy wire

The heavy wire staple is the thickest type of staple and is the one to use when the job demands a robust staple. Due to its thickness, it takes up a more substantial area when used compared to its fine and medium wire counterparts. But it provides higher holding power and is excellent when joining on wood or plastic on thick surfaces. The heavy wire is often you in house construction and in applications where you need a really robust joining.

Applications:

Furniture framework, Roof shingles, House manufacturing, Packaging

Our heavy wire staples:

JK555 JK557 JK560 JK561 JK590 JK783Guage

Many manufacturers state the wire diameter in the measurement gauge. It works as following the higher the gauge number is, the thinner the wire is, the lower the gauge is the thicker the wire. See below how the gauge number relates to the wire type.

| Gauge | 22 | 21 | 20 | 19 | 18 | 16 | 14 | 12 | 10 |

|---|---|---|---|---|---|---|---|---|---|

| Fine wire | x | x | x | ||||||

| Medium wire | x | x | |||||||

| Heavy wire | x | x | x | x |

How to choose the correct staple crown

The staple crown is the top middle part of the staples holding the two legs together. There are three types of crowns (narrow crown, medium crown, wide crown), and they all have their capabilities and uses.

Narrow Crown

The narrow crown is the smallest type of crown. It is easy to hide in applications after joining. It covers a smaller area then medium and wide crown staples. Often used for finish and trim and other delicate jobs, but it is also great for wood and panel work. A great choice when you want to save raw material and cut manufacturing costs.

Applications:

Molding, Cabinets, Trim, Paneling, Drawers, Upholstery, Giftboxes, Fruitboxes

Our narrow crown staples:

JK690 JK781

Medium Crown

The medium crown is as its name the crown type that comes in between narrow and wide crown staples. Used when you need to cover a larger area on your material than narrow crown allows you to do. It has more uses than a narrow crown staple and is often used in home construction.

Applications:

Furniture, Pallet, Crate, Sheathing, Subflooring, Packaging

Our medium crown staples:

JK670 JK680 JK689 JK777 JK779 JK782 JK783

Wide Crown

Of all the crown widths, this is the broadest crown type. Wide crown staples have a lot of similar uses as medium crown staples. When esthetics is not as necessary, a wide crown staple is a great choice. It covers a large area then narrow and medium crowns. Josef Kihlbergs wide crown staples are made for carton closing.

Applications:

Carton closing, Packaging

Our wide crown staples:

JK555 JK557 JK560 JK561 JK590How to choose the correct staple leg length

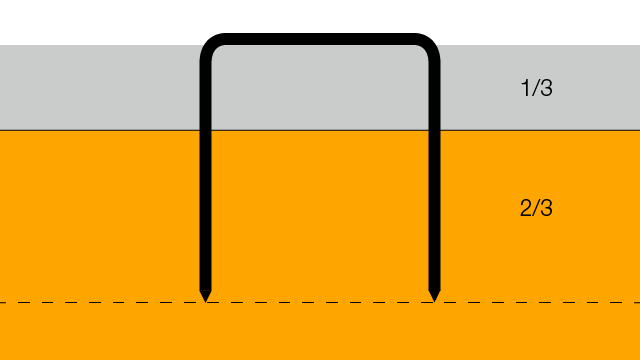

Getting the right staple length is crucial when deciding which staple you should choose. The thickness or density of the material you are fastening determines what leg length you should use for your application. See below for how you easily can decide which staple leg length your application needs.

Standard rule

An excellent rule for choosing the right staple length for your application is to take the thickness of the material your fastening and multiply it by three. So if the material you are fastening is 6mm thick, you should go with a staple length of 18mm. If you cannot add the desired length to your material, we recommend the closest shorter leg length available.

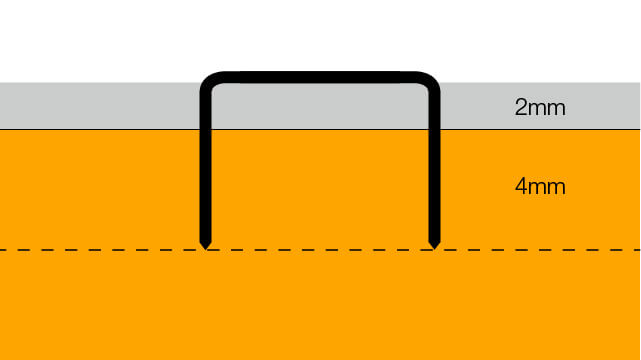

Thin material

If your application is using fabric or other thin material, we recommend adding 4mm to the thickness of the material used. So if your material is 3 mm thick, you use 7mm leg length. If you cannot add the desired length to your material, we recommend the closest shorter leg length available.

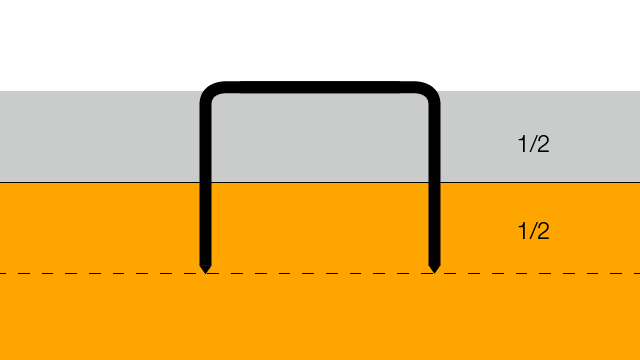

Hard material

To get a robust joining when fastening to hard materials such as hardwood, we recommend using a staple with leg lengths twice as long as the material that needs fastening. Then you can be sure it works as intended. If you cannot add the desired length to your material, we recommend the closest shorter leg length available.

How to choose the correct staple material

How to choose the right material for your application

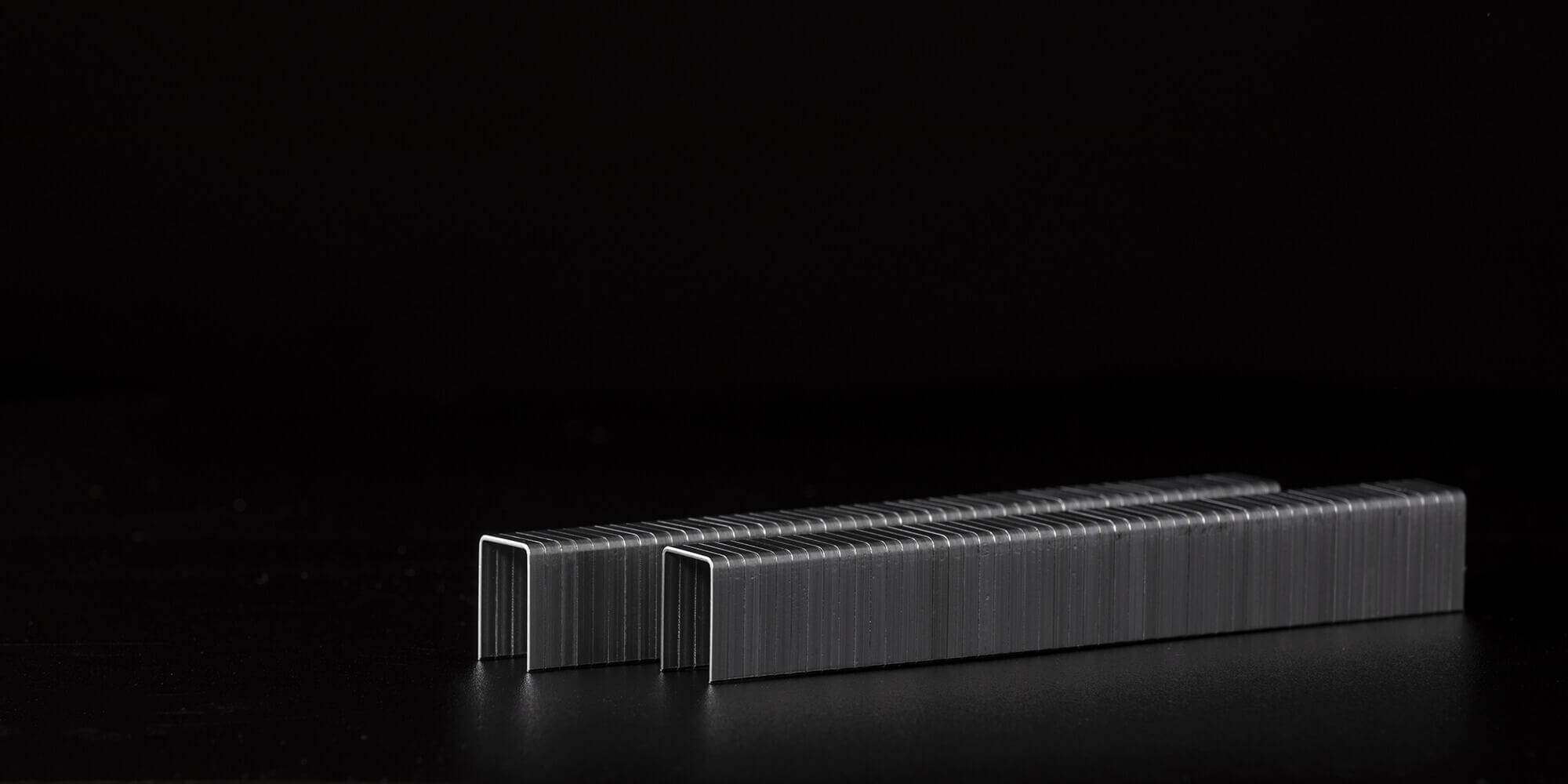

Galvanized staples

A galvanized staple is the most common staple type. The staple is a steel staple that is coated with a layer of zinc to be able to handle general corrosion better. A galvanized staple is comparable in strength and appearance to a stainless steel staple. If you need an all-around staple with a long life expectancy, a galvanized staple could be the right choice for your application.

At Josef Kihlberg, we produce premium galvanized staples that do not compromise the quality, which means that the staple has the correct holding power for the application and has the proper life expectancy.

Our galvanized staples:

JK53 JK561 JK665 JK670 JK680 JK689 JK690 JK777 JK779 JK781 JK782 JK783

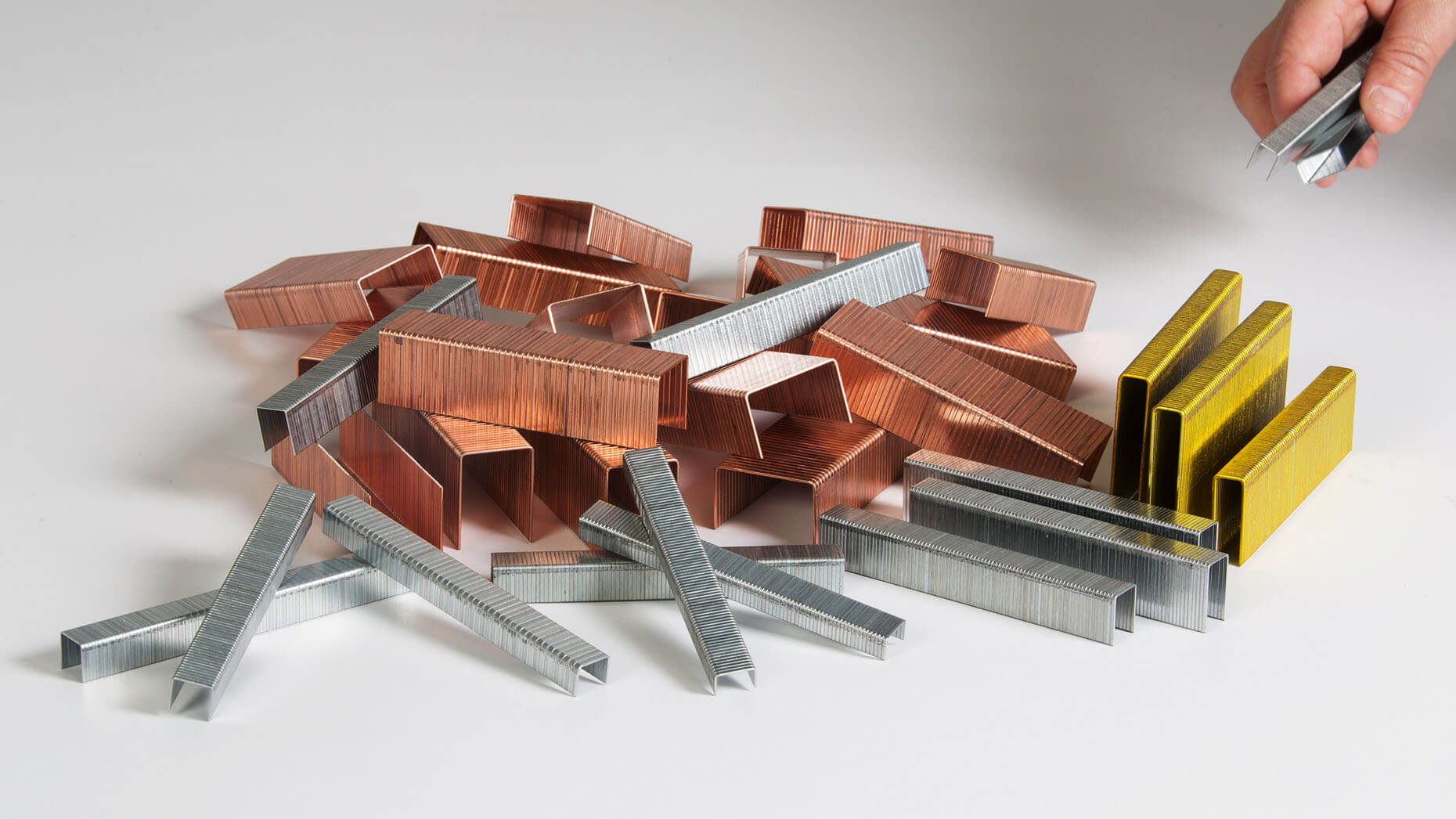

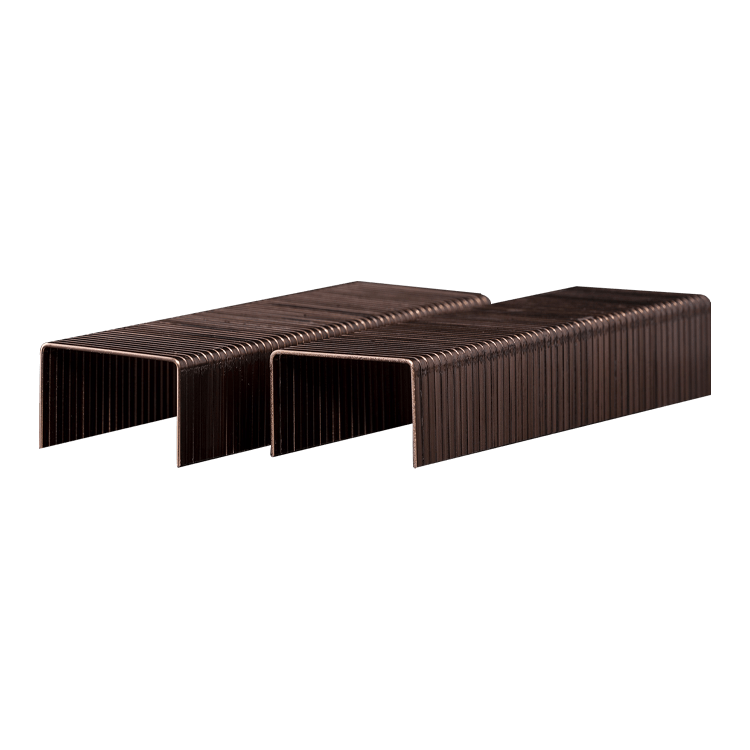

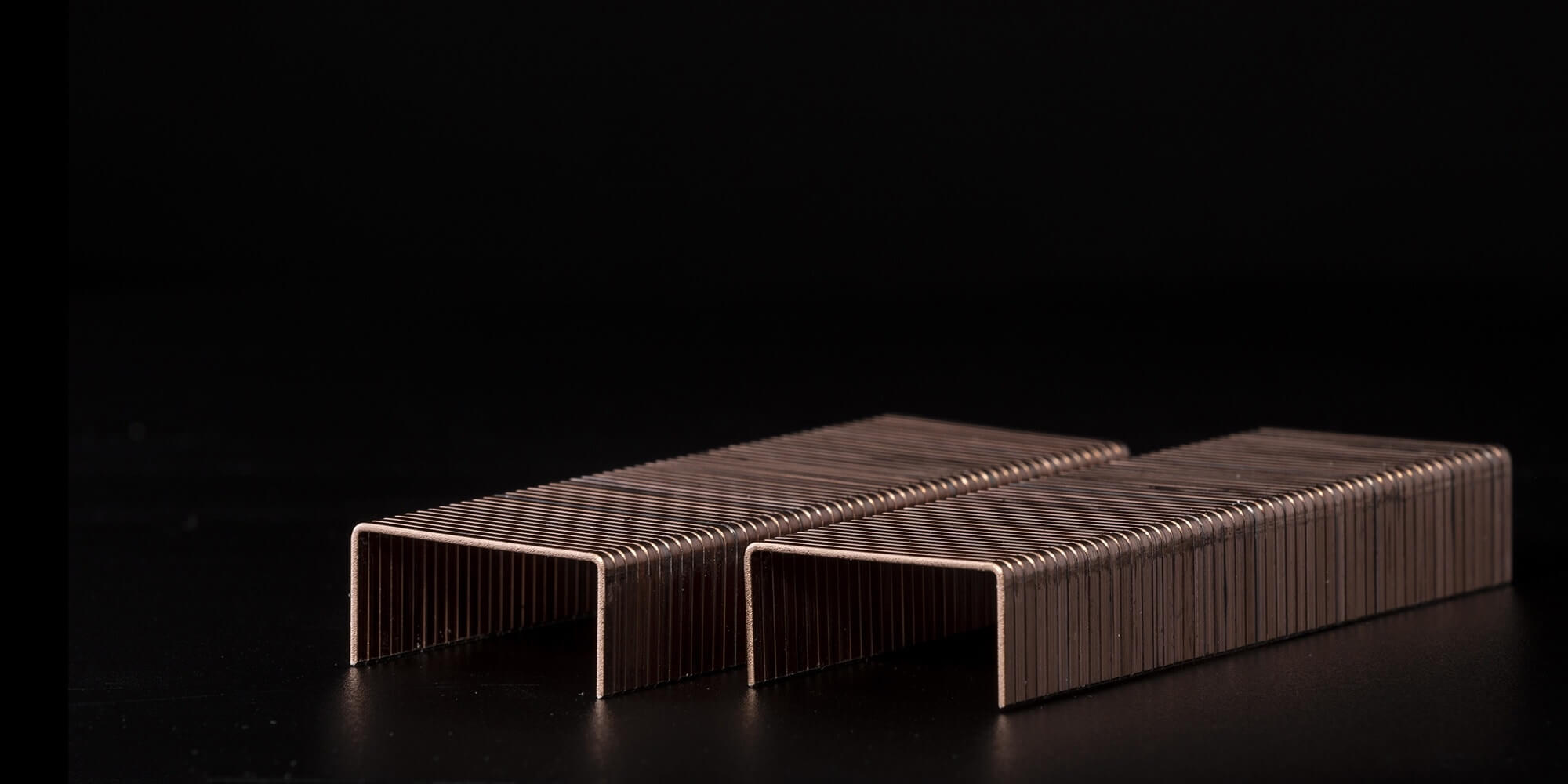

Copper coated staples

Copper coated staples are one of the best choices when it comes to beautiful clean aesthetics. It is excellent for transport packaging due to it works better than regular steel in non-humidity-controlled environments. Copper coated staples can oxidate faster in situations that are salty, hot, and acidic. Furthermore, copper-coated staples hinder electrical conductivity. It is the go-to staple for carton closing.

For the best copper-coated staples, there should be a certain amount of copper coating. We perfected this in our copper-coated staples. So you get premium quality staples that can handle the material, and that does the job for your application.

Our copper coated staples:

JK555 JK557 JK560 JK561 JK590

Aluminum staples

An aluminum staple is excellent for applications that need to avoid magnetism. The corrosion protection is more significant than a galvanized staple but has less corrosion protection than a stainless steel staple. Another great benefit of an aluminum staple is that you can easily cut through it without hurting your tool. Therefore it is widely used by sawmills when cutting trough wood.

Our aluminum staples:

JK680 JK782

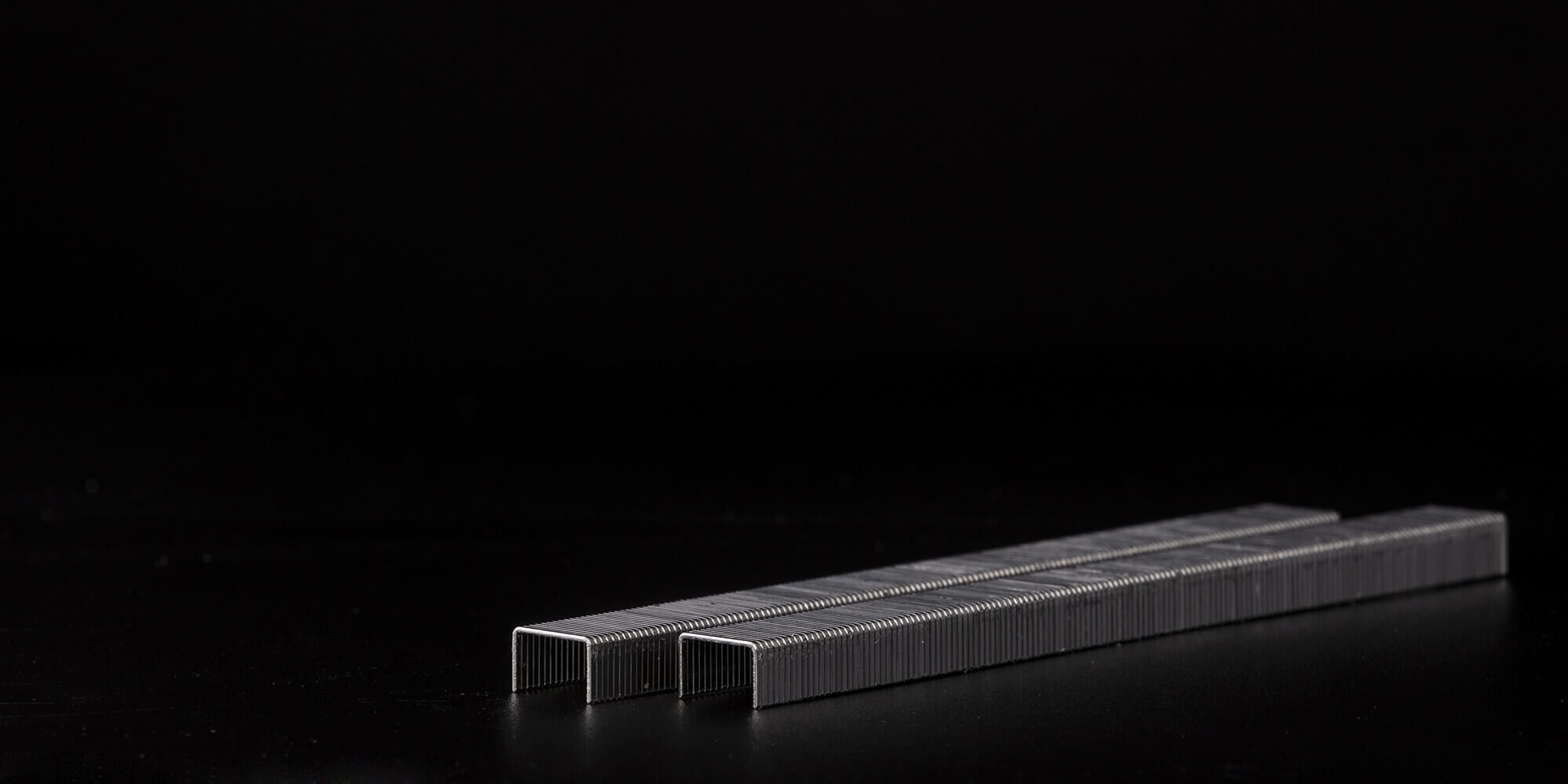

Stainless steel staples

A Stainless steel staple is for applications that need a higher level of corrosion protection or need to have a higher protection against heat. The standard stainless steel staples are 304 & 316. The 304 stainless steel staple is used for both indoor and outdoor use and protects against corrosion from milder oxidizing acids. The 316 stainless steel staple gives even greater protection against corrosion and is common when the application comes in contact with salty environments. A stainless steel staple is also a great choice in applications that need to look modern and high quality. A stainless steel staple is an environmental friendly staple, it breaks down by itself in nature, giving back important minerals to earth.

Our stainless steel staples:

JK680 JK777Custom color staples

If your application needs staples in a custom color, don´t hesitate to contact us

Staple point

The staple point is the first part of the staple coming in contact with the fastening material. The staple points come in various designs, where all are specialized to provide the correct holding power for the application. At Josef Kihlberg, we use the most common design, the chisel point design.

Chisel point staple

A chisel point staple has the design of the letter V, where the two flat inclined side meets at a sharp angle. The design makes it possible to drive the staple straight into the material to the crown of the staple.

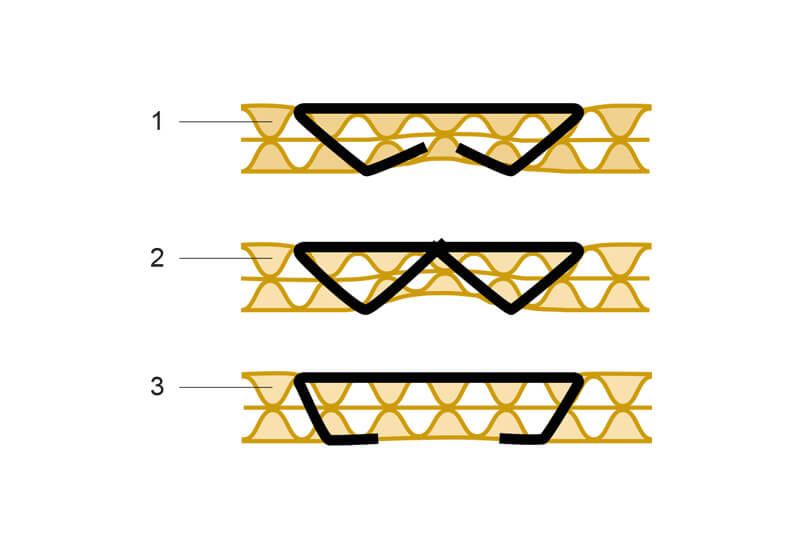

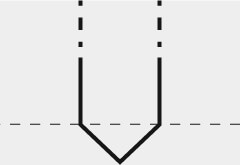

Staple Clinch

When we talk about staple clinch, we mean how the tool bends the legs of the staple. On many tools, you can adjust the clinch matching the application's needs. See below for how a correct staple clinch should be.

What a good staple clinch looks like

This example is from carton closing but translates to other applications with paperboard, cardboard, plastic, or fabric.

1. Good clinch

2. The leg length of the staple is too long or bent too much

3. The leg length of the staple is too short or not bent enough.